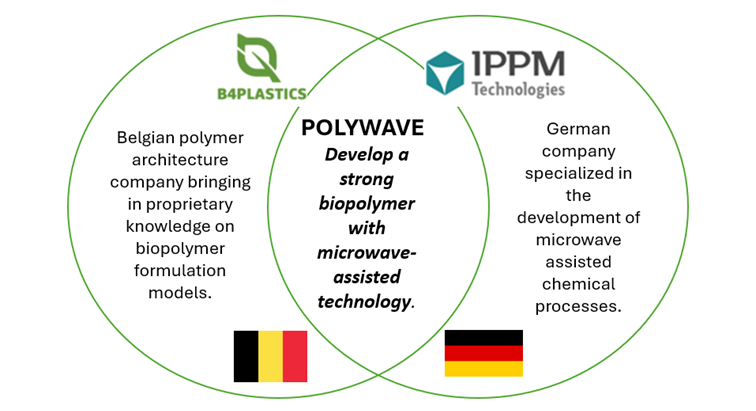

PolyWave

B4Plastics will develop a novel, strong and highly biodegradable polymer as well as a proprietary technology for the fabrication of novel bio-based building blocks

Vegan Leather is a member of CrossRoads2: Sustainable Energy, which is financed by Interreg V Flanders-Netherlands, the cross-border cooperation programme with financial support from the European Regional Development Fund.

The Problem

A deeper dive into the problem

This plastic pollution can harm the land and marine ecosystems and affects human health by the release of microplastics into the food chain. While societal awareness and European policies are driving the development of sustainable plastic products, current bio-based materials cannot match traditional plastics’ physical properties, such as strength and elongation. Thus, there is a strong market demand for robust and biodegradable polymers that can mimic plastics and degrade without leaving harmful residues.

The Solution

B4Plastics

IPPM Technologies

A deeper dive into the solution

IPPM Technologies will upscale a process for production of novel bio-based building blocks based on a proprietary microwave-assisted continuous-flow technology in commercial scale, which will drastically reduce the energy use and reaction time needed. The process development will include the transfer of information and learning from lab-scale to pilot plant scale and verification of the intended preparation of a commercial scale production process.

Biowaste streams will be used as feedstock, which makes the process independent of fossil resources.

The biopolymers produced from them have mechanical properties that are suitable for the production of a wide range of plastic products, while at the same time being fully mineralized in natural environments. This means that no microplastics are left behind.

PolyWave has received funding from Eureka (Project no. 5031) and Vlaio (Grant agreement No. HBC.2023.0739) under the Eurostars program.