Informative

FORTAN® for textiles – the best of both worlds

May 24, 2023

Referring to the European Commission’s shout-out “It’s time to make fast fashion out –of fashion”; B4Plastics might be able to turn this statement into reality with a newly developed bio-based material for high-performance and non-persistent fibers: “The Best of Both Worlds”.

The following alarming facts were shared by the European Commission:

- The fashion industry has the 4th highest impact on the environment and climate change, after food, housing, and transport.

- 5.8 million tonnes of textiles are discarded every year in the EU! Continue reading to find out how much this is per person.

- Only 1 % of the material used around the world for clothing is recycled into new clothing via so-called closed loops: “from clothing to clothing”.

A lifetime of textiles

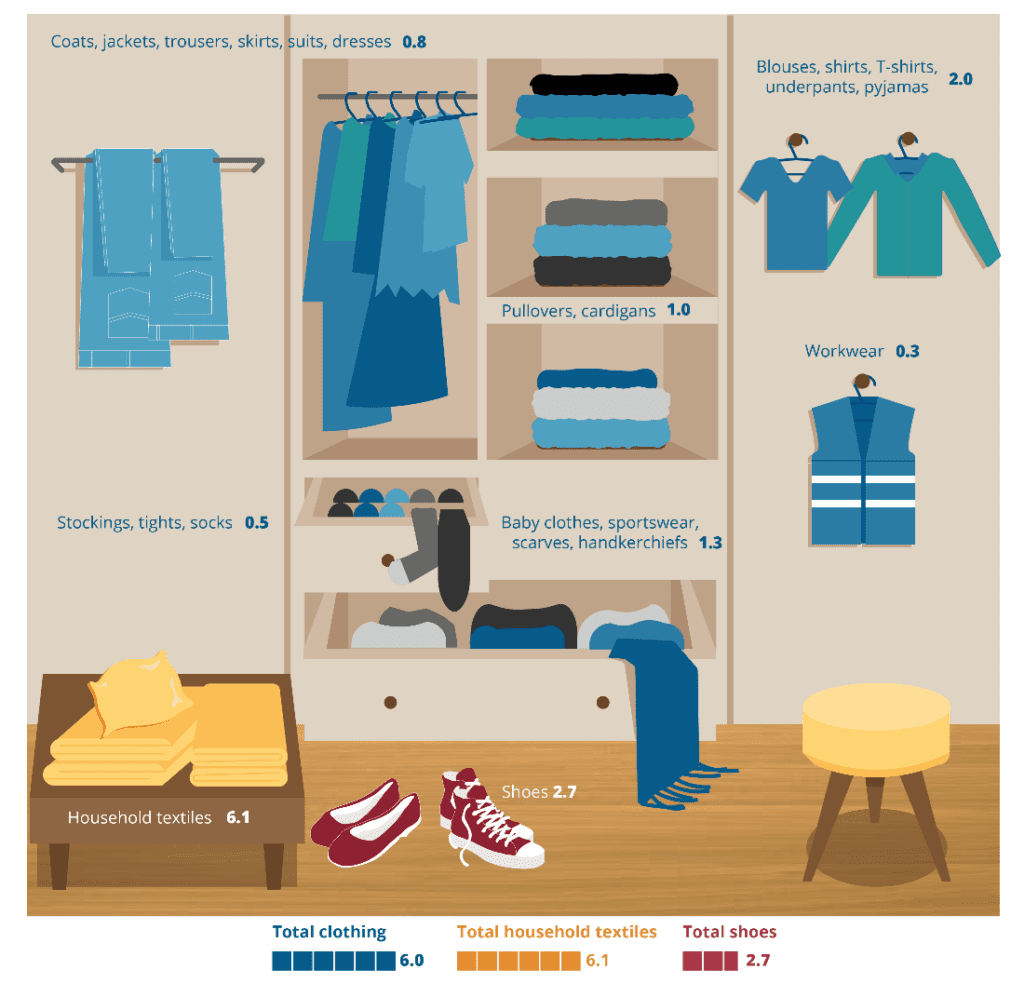

Households consume large amounts of textile products per year with an average textile consumption per person amounted to 6 kg of clothing, 6.1 kg of household textiles and 2.7 kg of shoes.

We must acknowledge that the use of synthetic fibers based on man-made polymers offer numerous advantages, including excellent mechanical properties and functionality, well thought-out production processes and less pressure on agricultural land in terms of water demand and fertiliser use compared to natural fibers.

Yet, in fact, we cannot continue to ignore the drawbacks.

Origin

About 1% of world crude oil production is used to manufacture synthetic fibers. This 1% counts for 42 billion liters of fossil oil, which can be compared with 16.800 filled Olympic Swimming Pools! The demand for synthetic fibers is expected to increase exponentially in the coming years. Global textiles production almost doubled between 2000 and 2015, and the consumption of textiles and shoes is expected to increase by another 63% by 2030.

Usage

Did you know that we are generating unintentional waste closer to our homes, in our homes, on a daily basis? Up to 5 grams of microfibers are being released per machine wash. Thousands of tonnes* of microfibers end up in the sewage system each year – in Belgium ALONE!

Not taken back by this figure?!

We challenge you to make a global calculation.

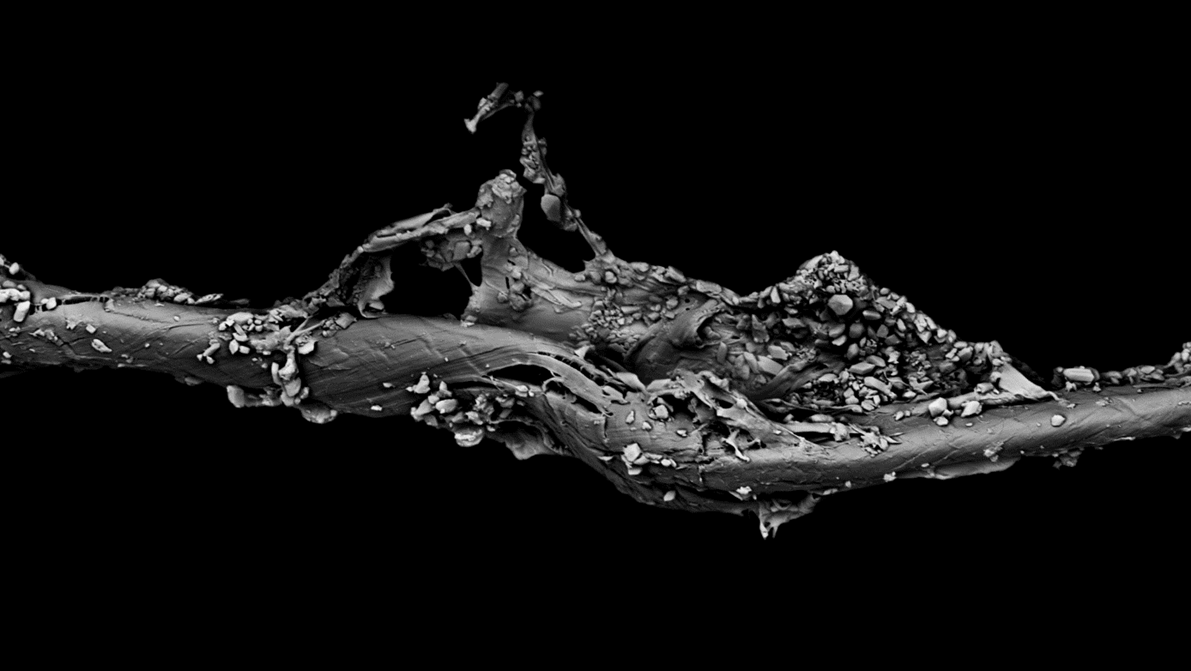

The majority of fibers are synthetic, such as PET polyester and polyamides, which are synthetic plastics that came in full production regime by the mid 20th century – at that time never designed with a clever end-of-life in mind. As a consequence, the microfibers from these PET polyesters and polyamides, being tiny fragmented plastics also called microplastics, fly around “by a breath” and get into our water, our feedstock and eventually under our skin, where they will persist for centuries!

*Calculation: 1054 mg/kg washed fabric x 5 kg of laundry per single use of washing machine x 104 times washing machine use per year x 5 M households = 2,600 tonnes microfibers released through washing per year in Belgium

Lifespan and quality

Fashion trends change very quickly and with this also the quality of products. This decreasing quality leads to even more microfiber particles being shedded from synthetic fiber products during their lifetime through wear, tear and wash.

When it comes to the lifespan of clothes per person, studies show that clothes that “fall out of use” have an average lifespan of 5.4 years and remain in the adult owner’s closet for about 4 years, while clothes for children and teenagers have the shortest lifespan.

End-of-life

Finally, when clothes are no longer worn, they often end up in residual waste, which in turn is incinerated or dumped on landfills, with the well-known images of textile heaps burned on our retinas. When clothes are sorted and reused (i.e. recycled), this counts for only a marginal 1% of all textiles worldwide.

Conclusion

A shift to a sustainable textile industry is urgently needed. This new industry should ensure a longer use of fabrics and support a new “way of life(style)”. We need to RETHINK and want to call on textile manufacturers to follow that same green path.

Solution

The European Union’s proposal for sustainable and circular textiles targets sustainable, recyclable and ethically produced textiles entering the EU market by 2030. Supported by this strong initiative, we at B4Plastics want to stand shoulder-to-shoulder with global brand owners, textile vendors and local governments. Only by clubbing together we can make a change – and a very much needed one!

FORTAN® meets the world

A solution is needed to address the impact of the plastic textile industry.

By combining the high-performance attributes of synthetic fibers, B4Plastics has developed a novel material that offers degradability of fibers at the micro-particle level, presenting the brand-new and urgently needed non-persistent microplastics textile from its strong material FORTAN®. The Best of Both Worlds.

FORTAN®, as part of the FortePlastics technology platform, strikes a balance of superior performance, resistance to wear, and long-term biodegradability.

Mostly made from bio-based feedstocks, FORTAN® reduces dependence on fossil feedstocks and contributes to a sustainable, new fashion normal. Most importantly, B4Plastics’ FORTAN® material is designed to be non-persistent in natural environments, breaking down to CO2 and biomass within years to decades depending on the external factors and its application – as opposed to the current 400-600 years lifespan of microplastics.

Change is coming. Are you joining us on this mission?

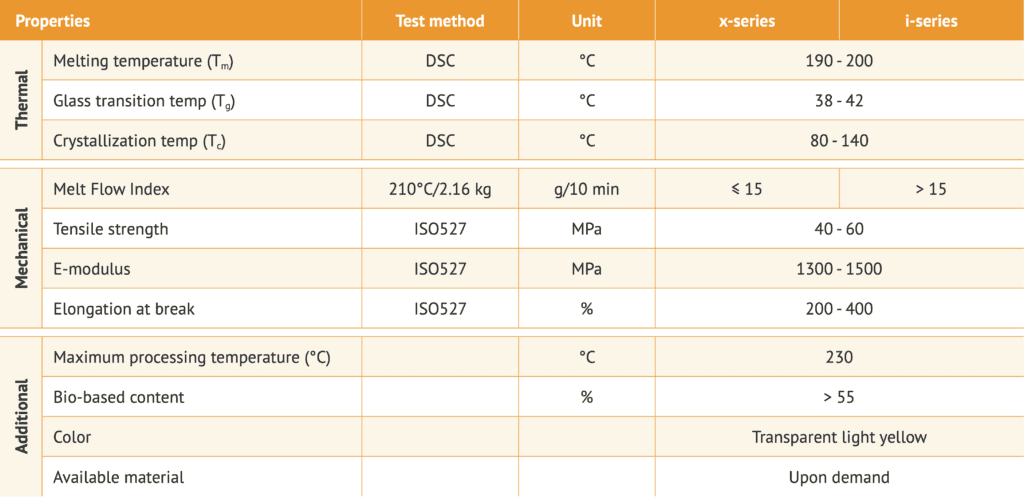

The unique added values of FORTAN® compared to commonly used, mostly fossil fibers:

- +100 MPa tensile strength under optimized extrusion conditions at controlled degradability

- Ca. 55% biobased content (typically from waste streams)

- Steerable degradability between 12-120 months in habitats of choice

- High to extreme durability and wear resistance

Discover our specifications of FORTAN®.

Partner up – building the New Plastics Economy is a practice best done together.

- Want to learn more about FORTAN®, B4Plastics and our projects? Visit the FortePlastics page on www.b4plastics.com.

- Ready to explore a collaboration with B4Plastics? Do not hesitate to reach out through our B2B contact form.

- Samples are being queued and shipped firstly to the most committed partners in the “New Fashion Industry”.

Don’t miss a thing! Stay up to date with our progress: Subscribe to our newsletter and follow us on LinkedIn and Facebook.

____________________

This article was co-authored by Felicitas Pellenghar, Hogne Ulla, Sil Nevejans and Leen Thys from B4Plastics.

Sources and further reading

- B4Plastics – FORTAN® The strongest material we can imagine, that is still degradable in a natural habitat. Accessed 4 May 2023.

- Enerdata (accessed 4 May 2023)

- European Commission LinkedIn post. Accessed 24 April 2023, from https://www.linkedin.com/company/european-commission/

- European Commission press corner. Questions and Answers on EU Strategy for Sustainable and Circular Textiles. Accessed 4 May 2023.

- European Environmental Agency. Accessed 21 January 2023.

- “Age and active life of clothing” Text

- Laitala, K. and Klepp, I.G.

- Falco F de, Gentile G, Di Pace E, Avella M, Cocca M (2018) Quantification of microfibres released during washing of synthetic clothes in real conditions and at lab scale⋆. Eur. Phys. J. Plus 133.

- Zheng J, Suh S (2019) Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 9:374–378.